Cellulose fibres provide excellent crack control due to the fibre properties to include: high fibre surface area, close fibre spacing, and excellent bonding within the hydrated cementitious matrix (Soroushian 1996).

Cellulose fibres are used to improve impact resistance and increase surface durability to plastic shrinkage cracking (Buch 1999).

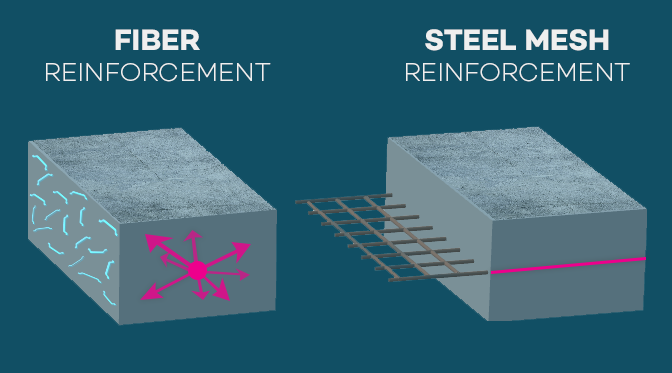

There are different materials are used for concrete fibre manufacturing. These different materials used lead to concrete performance features and benefits specific to job-type. The efficacy of a fibre in the concrete is generally based on two parameters: shape and material type.

The influence of shape on fibre-concrete bond is discussed in a previous article (See Shapes of Fibres).

When the concrete fibre is mixed into fluid concrete, some of the paste volume of the concrete mix saturates the surface of the concrete fibre. As the concrete cures and hardens, the fibre is mechanically anchored into the hardened paste. This phenomenon is similar to the action of the cementitious paste hardening around grains of sand and rock. Where the sand, rock, and fibre become an effective part of the concrete composite.

Concrete fibres which are often time’s steel or plastic can be smooth. A smooth fibre will not offer the same type of irregular shape as the grains of aggregate to help form the mechanical bond. Instead of an efficient load transfer, a smooth fibre might experience ‘fibre pull-out.’

Fibre pull-out refers to the action of a fibre that has not mechanically or chemically bonded to the hardened matrix of concrete. During the application of service loads, if the fibre is engaged through the paste, the lack of bond at the interface between the fibre and the hardened will render the fibre useless. The fibre will be pulled from the hardened matrix and offer little to no resiliency to the tensile loads it was originally intended to absorb.

Cellulose fibres provide these feature and benefits due to the toughness as well as their ability to bond to the hardened paste. The cellulose fibre has a porous surface area to allow for the fluid paste of the concrete to coat the fibre. As the fluid paste hardens it anchors the cellulose fibres into the concrete. The cellulose is also resistant to the alkaline environment of the cementitious paste which ensures that the toughness of the material won’t degrade over time. More over, as the cementitious matrix continues to densify overtime, it will further anchor the cellulose due to a refined matrix.

Jon S. Belkowitz, PhD