Steel reinforced concrete as composite material, continues to be a popular choice of building material for tension/compression strength characteristics, linear elasticity behavior, compatible thermal expansion/contraction and increased durability.

Reinforced concrete’s durability depends highly on concrete cover isolating/protecting steel from corrosion.

One of the main drawbacks in using reinforcing steel is the propensity to corrode due to environmental factors of where concrete is used. The likelihood of corrosion caused by chloride attack or carbonation increases in areas with high levels of water, natural corrosives and acids, and saltwater environments.

For example, testing done on New Zealand wharf structures indicated that for uncracked concrete elements, chloride attack of roughly 0.5 – 1mm per annum (non-linear), with ingestion rate varying, depending on concrete mix and maintenance. This implies that under regular maintenance conditions, 100mm cover may effectively be reduced to 50mm in 50 years and zero in 100 years. Cracking and corrosion will start as soon as chloride and oxygen encounter the steel. Once reinforcement is exposed to oxygen, the corrosion process excels through conductivity of steel.

The result is unsightly looks/stains, increased cracking, stresses and movement, and then ultimately – early failure of the reinforcement and the concrete entirely. Since reinforced concrete is designed to perform with the reinforcement intact, reduction in reinforcement strength contribution due to weakened, rusted, debonded or compromised steel will nullify calculation. Even though corrosion happens slowly, failure often happens unexpectedly and unpredictably. Concrete structures are commonly designed to withstand very high loads – so when failure occurs, the consequences can be catastrophic.

Urgent remediation shall be required with any sign of compromising to structural integrity. Remediation is not only a costly exercise; it is also a challenge to meet initial design capacity. Engineers and Asset Managers should rather aim to prevent remediation through appropriate design and full life cycle maintenance scheduling that is stipulated as part design.

Whilst plain concrete provides a barrier to corrosion due to durability and the lack of permeability, variables that exist in materials, workmanship and lack of maintenance can mean that the risk of corrosion is much higher when less care is taken in the design, the preparation and execution of a concreting job. Steel mesh and rebar (and even tie wires!!!) can end up very near the finished surface, where they are exposed to contaminants and corrosives with little natural protection.

Once the corrosion process starts it excels consistently and predictably until the source steel is all but totally consumed and turned into iron oxide (rust) where it has no ability to meet structural demand. At this point, the overall structure becomes vastly weaker compared to its original state since the concrete also becomes compromised as steel contributes to stress cracking due to oxide jacking. Plain concrete is too brittle to resist or absorb these stresses, and cracks and splits to accommodate the movements and dissipate the stresses.

The corrosion potential accelerates because the now-split concrete is less capable of shielding the steel from corrosives than it was before. More water or contaminants can rapidly enter the concrete uninhibited through the cracks and get straight to the steel within. Unfortunate, considering the difficulty and sometimes impossibility to replace or repair steel in situ.

Engineers need to consider different ways of improving the durability and corrosion resistance of concrete in order to protect steel. Fibre reinforced concrete can mitigate corrosion of reinforcing steel, and the ways in which the fibre can help to address the risks and reduce the problems with corrosion from happening. Fibres can improve the concrete consistency and create a more homogenous cross-section allowing even stress distribution under loading.

Reduced surface cracking:

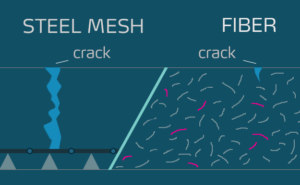

While the steel reinforcing is properly shrouded in the concrete, it is likely to stay corrosion free. The alkaline concrete environment helps to protect reinforcing steel in the absence of cracks and especially cracks > 1mm. Cracks form pathways for corrosive elements, which clearly increase the probability and rate of corrosion. Fibre ensures the surface of the concrete is markedly less prone to cracking, therefore ensuring the integrity of the finished surface stays crack free for longer. Even micro fibres can markedly increase the ability of concrete surfaces to avoid cracks. When cracks do occur, they tend to be much smaller and more controlled in fibre concrete than with steel mesh or rebar alone. Reduced crack size is particularly important in providing a watertight surface which prevents the ingress of corrosive elements.

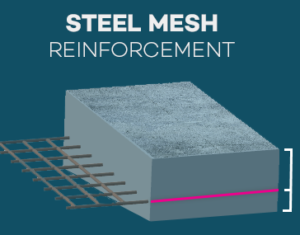

Improved concrete cover:

Fibre reinforcement can increase concrete cover where secondary reinforcement, which is typically closer to the surface, is replaced. Fibre reinforced concrete will also provide better support for the embedded steel reinforcing during construction. Movement in relation to formwork/supports from poor workmanship, accidents or pouring forces can lead to reinforcing moving via gravity to the bottom of the job, bringing it closer to the external finished surface. The further to the centre of a slab the steel remains, the less chance there is of it being exposed during its life as it is better shrouded in protective concrete from the outside elements.

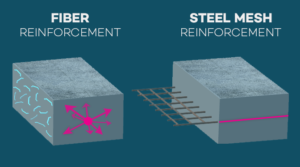

Eliminate steel mesh and rebar:

The design of some fibre reinforced concrete elements can eliminate steel mesh or rebar to achieve the same performance. For environments where there is a high risk of corrosives, this can be the best solution overall. Especially when the fibre chosen is synthetic and therefore will not corrode at all. Even in cases where steel fibre is chosen, the separated nature of the fibre through the concrete matrix, means that any individual fibres that may suffer corrosion, will not transfer the process to the rest of the fibres over the life of the product. Case studies have also shown that the surface area of a fibre is too small to case any oxide jacking – meaning that steel fibre reinforced concrete will not experience enhanced corrosion as the cases for exposed steel/rebar reinforcement.